The Science of Bubbles in Metal: How is Aluminium Foam Made?

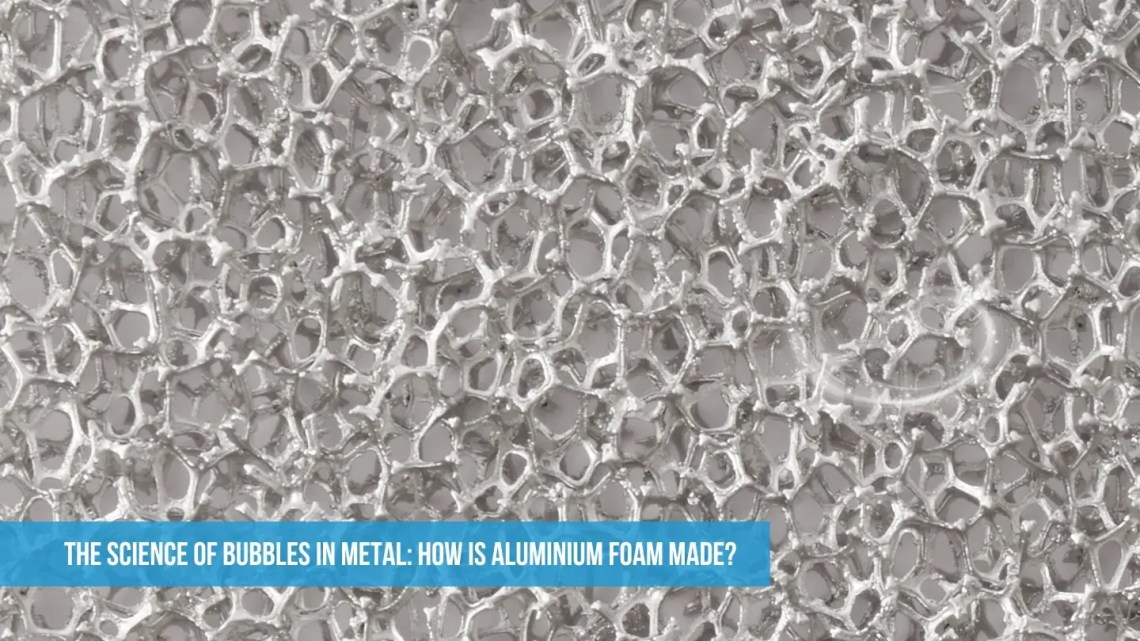

September 11, 2025 Off By ShilpentAluminium foam is a porous form of aluminium or its alloys. It has been known for more than fifty years, but its use has remained limited. The main challenge was the difficulty in producing foams with a uniform structure and predictable properties. Many of these problems have been resolved as production methods have improved with time. Nature inspired the concept of metal foams. Scientists were inspired by materials like wood, bone, coral, and pumice as they combine low weight with strength and energy absorption. Modern technology now allows manufacturers to create aluminium foams that share these qualities.

Today, aluminium foam has many applications across industries. It is valued for being light, strong, and efficient in absorbing energy. Different production methods give rise to different types of foams, each with its own set of properties.

Production of Aluminium Foam

Aluminium foam can be made using different methods. One of the most common methods to make aluminium foam is by injecting gas or using blowing agents in molten aluminium to form bubbles. Materials such as salt, polyurethane foam, or hollow spheres may be added during the process and later taken out or burnt away to leave pores. Another technique relies on powder metallurgy, in which aluminium powder mixed with certain additives is heated until it expands into a foam. Advanced methods, such as additive manufacturing, allow for precise control of shape, though the process is still quite expensive.

Materials and equipment must be prepared carefully before production. Aluminium powder, foaming agents, fluxing agents, and release agents are mixed in proper ratios. Because the materials can be hazardous, it’s essential to wear protective gear, maintain proper ventilation, and keep fire‐safety equipment handy. Moulds and tools must be spotless, and the furnace or torch needs a properly placed crucible with accurate temperature control.

Process Steps:

Preheating of Furnace: Heat the furnace or torch to the required temperature (usually 700°C–1000°C).

Melting and Stirring: To melt aluminium powder evenly, place the powder or granules into the crucible and stir them gently.

Foaming agent: Introduce the foaming agent. It releases gas and creates bubbles in the molten metal.

Fluxing agent: It is added to remove impurities and improve bubble stability.

Transfer into moulds: Pour the mixture quickly into clean moulds before it starts to cool.

Cooling: Allow the foam to cool and harden completely inside the moulds.

Releasing agent/ Demould: After it solidifies, use a release agent to take out the foam and prevent it from sticking.

Refining: The foam can be polished, coated, or sanded to achieve the required look and properties.

Aftercare

After aluminium foam is made, it must be handled and stored properly to keep the material in good condition.

Aluminium foam is fragile; avoid dropping it or applying heavy pressure.

Store it in a cool, dry place, as moisture may cause corrosion and long-term damage.

Use a cotton cloth or a feather brush to remove dust and dirt carefully. This helps maintain the product’s appearance and performance.

Depending on use, the foam can be polished or coated for better strength or appearance.

Waste from production, such as unused material or crucibles, should be disposed of safely. Follow local rules for hazardous waste.

Properties and Applications Aluminium Foam

Aluminium foam is extremely light, with a density of only 0.1 to 0.4 times that of solid aluminium. It can absorb large amounts of energy, which makes it very effective for impact protection. Its porous structure helps block and absorb sound, giving it strong soundproofing ability. In addition, it is fire-resistant, as it does not burn or produce harmful smoke.

In the aerospace and automobile industries, aluminium foam is used for lightweight parts, crash protection, heat control, and noise reduction. In construction, it serves as insulation, fireproof panels, and wall materials. Defence and marine industries use it for blast protection, buoyancy, and light structures. In medicine and sports, it is applied in implants, prosthetics, helmets, and bicycle frames.

Closed-pore foam, with 80–98% porosity, is strong, absorbs impact, and blocks sound, making it suitable for transport and safety uses.

Open-pore foam allows gases and liquids to pass through, so it is used in filters, noise control tools, moulding, vacuum tables, and heat exchangers.

Porous aluminium, a type of open-pore foam, can replace materials like ceramics, plastics, and sintered metals.

Research is still finding new ways to use this material.

Conclusion

Producing aluminium foam is a complex task. The process requires thorough preparation, stepwise attention, and adherence to safety measures. When done properly, it can produce high-quality, strong and reliable foam. This blog has outlined how aluminium foam is made and how industries can tap into its special benefits and move towards a more sustainable, efficient future. At Shilpa Enterprises, the team has years of expertise and a clear understanding of how the material behaves. We help customers select the right option and ensure that each stage, from raw material to final product, is thoroughly checked for quality. Besides regular sheets, we also supply custom foam in different shapes, sizes, and levels of porosity.